Minimally invasive medical procedures and devices have revolutionized modern healthcare by reducing patient discomfort and lowering the risk of complications. For Trice Medical, this philosophy has always been at the core of their mission. However, when they faced persistent issues with obtaining reliable injection-molded components for their critical equipment, it became clear that a new partner was needed—one who could provide not just parts, but a true solution.

Recently, Mike Steen, President of Trice Medical, shared insights into the company’s long-standing relationship with AIM Processing. With over 15 years of experience in the industry, Mike highlighted how their partnership has grown and evolved, emphasizing the value that AIM brings to the table through quality, innovation, and personal service.

Trice Medical: Leading the Way in Minimally Invasive Care

Trice Medical is a leader in developing minimally invasive medical devices designed to improve patient outcomes while reducing overall healthcare costs. Their products, such as the Tenex ultrasonic surgical aspirator and disposable arthroscopes, are used in settings like ambulatory surgical centers and physician offices—places where cost efficiency and accessibility are key.

The AIM Processing Advantage: More Than Just a Supplier

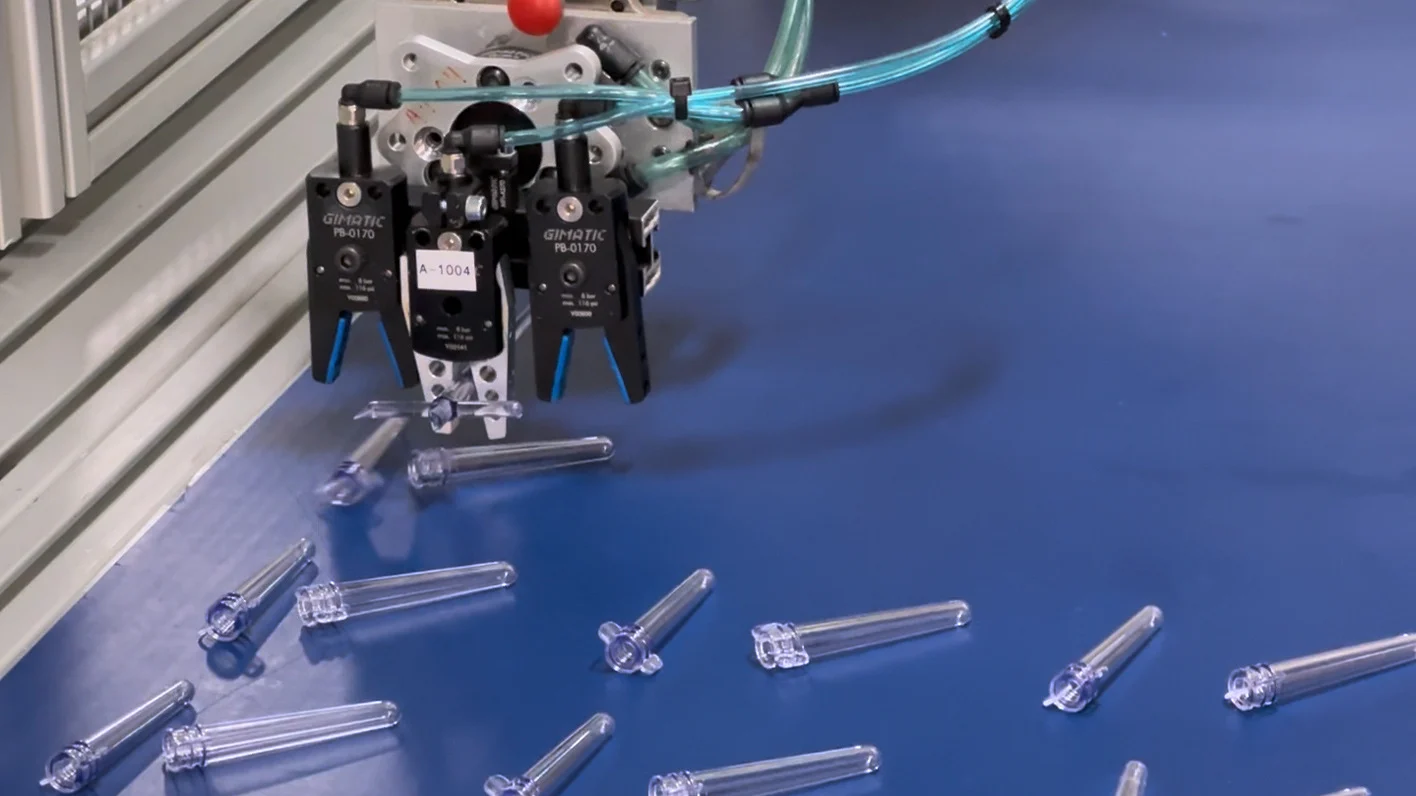

AIM Processing plays a crucial role in manufacturing the injection-molded components for Trice Medical’s Technics line. But beyond just producing parts, AIM offers process optimization, quality control, and engineering support that directly enhance the performance and consistency of Trice’s devices.

Mike emphasized that this level of expertise and collaboration has allowed Trice to focus on what matters most—innovation and clinical impact—while trusting AIM to handle the complex manufacturing challenges behind the scenes.

A Partnership Built on Trust and Personalized Support

When Trice first approached AIM, they were a small startup with limited experience in injection molding. Previous suppliers had failed to meet their needs, leaving them frustrated and struggling to scale. That’s when AIM stepped in with personalized attention and a hands-on approach that made all the difference.

“We weren’t getting the time or attention we needed from larger suppliers,†Mike said. “AIM’s personal touch made a big difference in helping us overcome those early challenges.â€

Overcoming Manufacturing Challenges Together

Before working with AIM, Trice faced significant issues with inconsistent component quality and non-conformance. AIM quickly identified the root causes and helped refine the manufacturing process, leading to a dramatic improvement in reliability and performance.

Mike noted that AIM’s ability to identify critical parameters and implement better controls was instrumental in stabilizing production and ensuring consistent output.

Key Challenges Faced:

- Inconsistent component reliability and quality

- Struggles with non-conformance

- Lack of expertise in refining the manufacturing process

Seamless Tool Transfer: A Test of Partnership

One of the most critical moments in the Trice-AIM relationship was the tooling transfer from a previous supplier. Tooling transfers can be risky, but AIM ensured a smooth transition with no disruptions.

“Tooling transfers are prone to problems, but AIM made sure everything went smoothly,†Mike said. “We had zero issues during the entire process.â€

A Decade of Excellence and Growth

Since around 2014–2016, Trice Medical has partnered with AIM Processing for nearly a decade. Over time, the relationship has deepened, especially in the area of quality assurance. Mike praised AIM’s quality team for their expertise and reliability, calling them a valuable asset to the company.

Onshoring: A Strategic Advantage

One of the standout features of AIM Processing, according to Mike, is its domestic presence. In an industry increasingly reliant on offshore manufacturing, having a U.S.-based partner has provided Trice with greater supply chain stability and regulatory compliance.

“Many companies should take notice of competencies that are stateside,†Mike said. “AIM’s domestic presence is a huge differentiator in ensuring supply chain reliability and meeting tight regulatory requirements.â€

Focus on Innovation, Not Manufacturing

Thanks to AIM’s support, Trice Medical has been able to focus more on product development and clinical innovation rather than being bogged down by manufacturing issues. This shift has been vital for the company’s growth and success.

Key Benefits of the Partnership:

- Reliable part quality

- Proactive communication on material changes and part number updates

- Significant reduction in failure rates and yield loss during manufacturing

- Expert engineering support to fill competency gaps

- Domestic manufacturing, ensuring supply chain stability

A Lasting Relationship of Trust and Success

The Trice Medical and AIM Processing partnership has delivered impressive results, including a significant drop in product failure rates and improved manufacturing efficiency. Mike credits AIM’s reliability and expertise for allowing Trice to focus on what really matters: patient care and innovation.

With AIM’s support, Trice continues to grow and evolve, confident that their manufacturing needs are handled by a trusted partner. This collaboration stands as a powerful example of how the right supplier relationship can drive long-term business success.

Want to learn more about this successful partnership? Watch our exclusive video featuring Mike Steen as he shares more insights into how AIM Processing has contributed to Trice Medical's ongoing success.

Â

Vending machines allow customers to freely choose to purchase products at any time of the day. People can buy the products he or she wants 24 hours a day a year.

The variety of products that vending machines can handle is another advantage brought by this technology in business. Use this machine to sell various products, such as beverages, snacks, cigarettes and other products. This concept is also applicable to some service provision industries, such as bus stations, hotels and other public utilities.

Most vending machines are located at strategic points, which can be convenient and time-saving, because you can guarantee that you get what you want.This is a one-time investment and does not require a large amount of operating expenses. Not hiring employees to reduce indirect costs will only increase the owner`s profit margin and make it a successful business.

If needed, the machine can be moved to other areas at any time and will continue to provide services as usual.

Beverage Vending Machine,Coffee Vending Machine,Drink Vending Machine,Tabletop Beverage Vending Machine

Dongguan Kaisijin Intelligent Technology Co., Ltd , https://www.oemsmartlock.com