How Robotic Welding Boosts Productivity for Manufacturers of Large Transportation Components

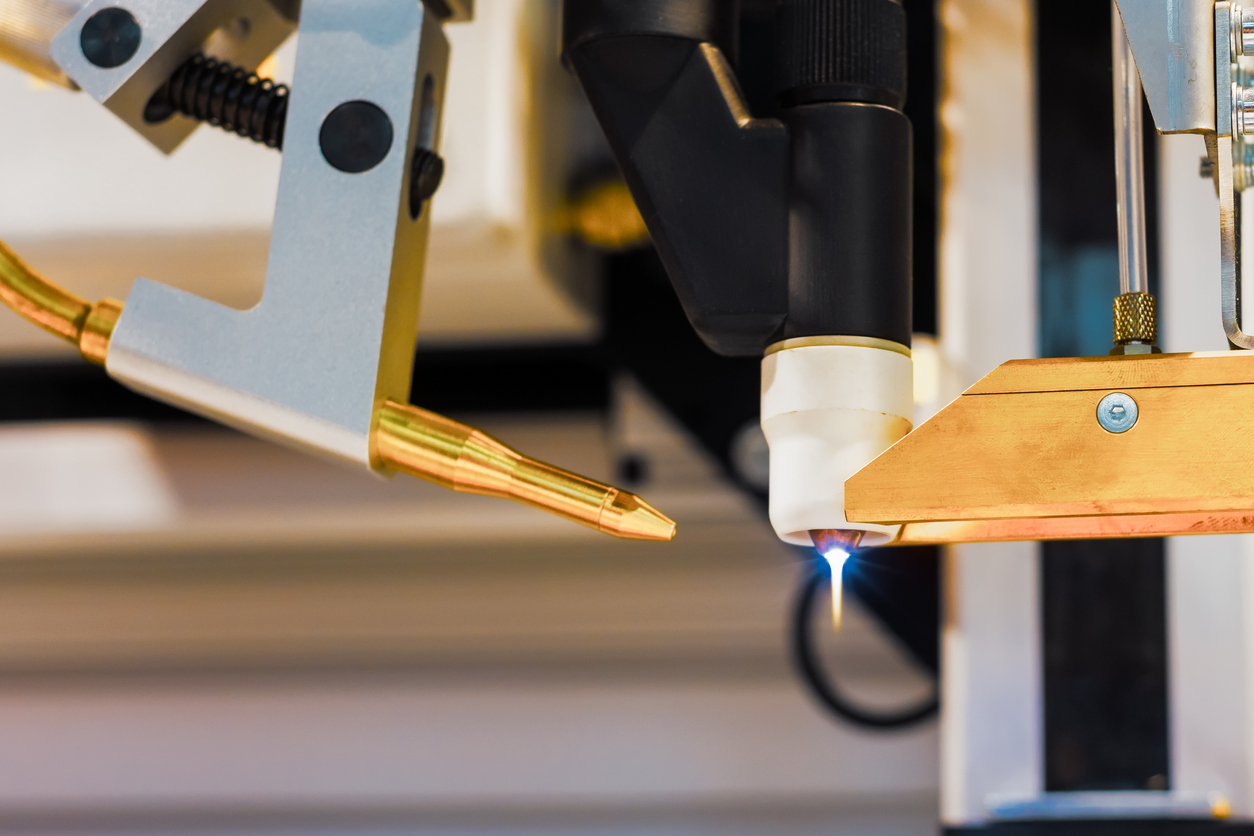

Robotic welding has become a game-changer for manufacturers in the transportation industry, especially those producing large and complex parts. While it's commonly associated with high-volume, repetitive tasks, modern robotic systems are now capable of handling intricate, large-scale components with precision and efficiency.

These advanced systems often include multiple robots working in sync, supported by sophisticated software that ensures consistent and high-quality welds. Compared to traditional manual methods, which can be slow, error-prone, and labor-intensive, robotic welding significantly improves productivity and reduces costs over time.

Key Features of an Efficient Robotic Welding System for Large Transportation Parts

Creating a productive robotic welding cell for large parts requires careful planning and design. One of the most important aspects is extensive programming, usually done offline using simulation tools. This helps prevent collisions and ensures smooth operation during the actual welding process.

Another critical factor is the robot’s reach. For large components, standard robotic arms may not be sufficient, so systems often incorporate mobility solutions like servo-driven tracks. These tracks allow robots to move along the part, increasing their effective range and enabling more complex welds without repositioning the entire component.

Realizing ROI with Robotic Welding: A Case Study from a Tier-1 Manufacturer

A recent example involved a tier-1 trailer bed manufacturer facing production bottlenecks due to high defect rates and inefficient manual welding. To address these issues, they partnered with Genesis Systems to implement a custom robotic welding solution.

The system featured a two-station setup, which improved loading and unloading times and reduced downtime. With two robots working simultaneously, the manufacturer was able to complete multiple welds at once, resulting in faster and more consistent results. This change led to a significant reduction in lead times and overall production costs.

Not only did the robotic welding cell deliver a quick return on investment, but it also enhanced the quality of the final product. The manufacturer saw fewer defects, increased output, and greater flexibility in meeting customer demands.

If you're looking to improve your manufacturing process or understand how robotic welding can benefit your business, check out the full case study on Genesis Systems’ innovative approach to large-part welding in the transportation sector.

Posted in Robotic WeldingSubmersible Pump Type Fuel Dispenser

Eight Hoses Submersible Pump Type Fuel Dispenser ,Eight Hoses Four Products Fuel Dispenser,Gasoline Eight Hoses Fuel Dispenser,Diesel Eight Hoses Fuel Dispenser

Henan Wenjia Energy Technology Co., Ltd , https://www.hnwjny.com