Welded fitting attaches the pipes and elements with the help of weld in order to make sure that it is leak proof and has strong connection. Because of its enduring connection and higher level of strength. It is extensively utilize over several industries some of them are given below:

Table of contents

- Welded Steel Fittings Specification

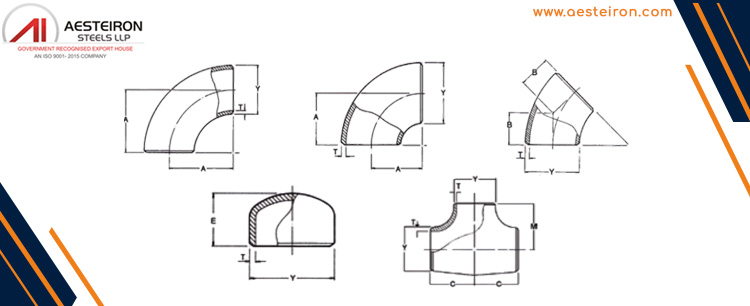

- Dimensions of Welded Fittings

- Welded Pipe Fittings Applications

- Seamless and Welded Fittings Standards

- HS Code for Welded Pipe Fittings

- Welded Carbon Steel Fittings Benefits

- ASME B16.9 Buttweld Elbow Dimension

- What is welded fittings?

- Difference Between Seamless and Welded Fittings

- Welded Tee Dimension

- Welded Pipe Reducer Dimensions

Welded Steel Fittings Specification

| Seamless Fitting Size |

|

|---|---|

| Welded fittings Size Range |

|

| ASTM Standards |

|

| Butt Weld Fittings Connection |

|

| Welded Black Iron Fittings Bending Radius |

|

| Welded Pipe Fittings Wall Thickness |

|

| Welded Carbon Steel Fittings Density |

|

| Welded Steel Pipe Fittings Temperature |

|

| ASTM A403 Welded Fittings Testing Methods |

|

| Specialized Welded Fittings Manufacturer in India, Buy Seamless and Welded fittings at Lowest Price in Mumbai | |

View ASTM A403 welded fittings sizes, dimensions and application

ASTM A403 welded fittings is the forged and rolled austenitic stainless steel fittings which are primarily utilize for pressure pipes. It can utilize in several areas of engineering industry and energy transformation factory, etc.

ASTM A403 standard consists various austenitic stainless steel grades. The below given table will provide you the available dimensions of welded fittings.

Dimensions of Welded Fittings

| NPS In. |

OD | Wall Thickness T | 90° Elbows | 90° Returns | 45° Elbows |

Crosses | Caps | Tees | Stub Ends | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| XS | ST | XX | 160 | Short R A |

Long R A |

Short R K |

Long R K |

B | C | E | C | G | F | ||

| 1 | 1.315 | 0.179 | 0.133 | 0.358 | 0.250 | 1 | 1-1/2 | 1-5/8 | 2-3/16 | 7/8 | – | 1-1/2 | 1-1/2 | 2 | 4 |

| 3/4 | 1.050 | 0.154 | 0.113 | 0.308 | – | – | 1-1/8 | – | 1-11/16 | 7/16 | – | 1-1/4 | 1-1/8 | 1-11/16 | 3 |

| 1-1/2 | 1.900 | 0.200 | 0.145 | 0.400 | 0.281 | 1-1/2 | 2-1/4 | 2-7/16 | 3-1/4 | 1-1/8 | 2-1/4 | 1-1/2 | 2-1/4 | 2-7/8 | 4 |

| 1/2 | 0.840 | 0.147 | 0.109 | – | – | – | 1-1/2 | – | 1-15/16 | 5/8 | – | 1 | 1 | 1-3/8 | 3 |

| 1-1/4 | 1.660 | 0.191 | 0.140 | 0.382 | 0.250 | 1-1/4 | 1-7/8 | 2-11/16 | 2-3/4 | 1 | 1-7/8 | 1-1/2 | 1-7/8 | 2-1/2 | 4 |

| 2 | 2.375 | 0.218 | 0.154 | 0.436 | 0.344 | 2 | 3 | 3-3/16 | 4-3/16 | 1-3/8 | 2-1/2 | 1-1/2* | 2-1/2 | 3-5/8 | 6 |

| 3 | 3.500 | 0.300 | 0.216 | 0.600 | 0.438 | 3 | 4-1/2 | 4-3/4 | 6-1/4 | 2 | 3-3/8 | 2* | 3-3/8 | 5 | 6 |

| 2-1/2 | 2.875 | 0.276 | 0.203 | 0.552 | 0.375 | 2-1/2 | 3-3/4 | 3-15/16 | 5-3/16 | 1-3/4 | 3 | 1-1/2 | 3 | 4-1/8 | 6 |

| 3-1/2 | 4.000 | 0.318 | 0.226 | 0.636 | – | 3-1/2 | 5-1/4 | 5-1/2 | 7-1/4 | 2-1/4 | 3-3/4 | 2-1/2* | 3-3/4 | 5-1/2 | 6 |

| 5 | 5.563 | 0.375 | 0.258 | 0.750 | 0.625 | 5 | 7-1/2 | 7-3/4 | 10-5/16 | 3-1/8 | 4-7/8 | 3* | 4-7/8 | 7-5/16 | 8 |

| 4 | 4.500 | 0.337 | 0.237 | 0.674 | 0.531 | 4 | 6 | 6-1/4 | 8-1/4 | 2-1/2 | 4-1/8 | 2-1/2* | 4-1/8 | 6-3/16 | 6 |

| 6 | 6.625 | 0.432 | 0.280 | 0.864 | 0.719 | 6 | 9 | 9-5/16 | 12-5/16 | 3-3/4 | 5-5/8 | 3-1/2* | 5-5/8 | 8-1/2 | 8 |

| 10 | 10.750 | 0.500 | 0.365 | 1.000 | 1.125 | 10 | 15 | 15-3/8 | 20-3/8 | 6-1/4 | 8-1/2 | 5* | 8-1/2 | 12-3/4 | 10 |

| 8 | 8.625 | 0.500 | 0.322 | 0.875 | 0.906 | 8 | 12 | 12-5/16 | 16-5/16 | 5 | 7 | 4* | 7 | 10-5/8 | 8 |

| 12 | 12.750 | 0.500 | 0.375 | 1.000 | 1.312 | 12 | 18 | 18-3/8 | 24-3/8 | 7-1/2 | 10 | 6* | 10 | 15 | 10 |

| 16 | 16.000 | 0.500 | 0.375 | – | – | 16 | 24 | 24 | 32 | 10 | 12 | 7* | 12 | 18-1/2 | 12 |

| 14 | 14.000 | 0.500 | 0.375 | – | – | 14 | 21 | 21 | 28 | 8-3/4 | 11 | 6-1/2* | 11 | 16-1/4 | 12 |

| 18 | 18.000 | 0.500 | 0.375 | – | – | 18 | 27 | 27 | 36 | 11-1/4 | 13-1/2 | 8* | 13-1/2 | 21 | 12 |

| 22 | 22.000 | 0.500 | 0.375 | – | – | – | 33 | – | 44 | 13-1/2 | 16-1/2 | 10 | 16-1/2 | – | – |

| 20 | 20.000 | 0.500 | 0.375 | – | – | 20 | 30 | 30 | 40 | 12-1/2 | 15 | 9* | 15 | 23 | 12 |

| 24 | 24.000 | 0.500 | 0.375 | – | – | 24 | 36 | 36 | 48 | 15 | 17 | 10-1/2 | 17 | 27-1/4 | 12 |

| 30 | 30.000 | 0.500 | 0.375 | – | – | 30 | 45 | 45 | 60 | 18-1/2 | 22 | 10-1/2 | 22 | – | – |

| 26 | 26.000 | 0.500 | 0.375 | – | – | – | 39 | – | 52 | 16 | 19-1/2 | 10-1/2 | 19-1/2 | – | – |

| 34 | 34.000 | 0.500 | 0.375 | – | – | – | 51 | – | – | 21 | 25 | 10-1/2 | 25 | – | – |

| 42 | 42.000 | 0.500 | 0.375 | – | – | 42 | 63 | – | – | 26 | – | 12 | – | – | – |

| 36 | 36.000 | 0.500 | 0.375 | – | – | 36 | 54 | 54 | – | 22-1/4 | – | 10-1/2 | 26-1/2 | – | – |

Welded Pipe Fittings Applications

- Petrochemical

- Chemical processing

- Water treatment

- Power generation

- Oil and gas

Refer various welded fittings standard such as ASME B16.9 and MSS SP-43

Welded fitting which are manufactured through ASME B16.9 standard covers the scope, size, material, pressure rating, etc. Whereas, welded fitting which are fabricated from MSS SP-43 standard are utilise for low pressure and corrosion resistant applications.

The below table of Seamless and Welded Fitting ASTM standards will provide you more details of standard and in which form and condition it is been used for.

Seamless and Welded Fittings Standards

| ASTM Standards | A403 | A815 | A234 | A420 | A361 | A366 | A363 |

|---|---|---|---|---|---|---|---|

| Material Specification |

|

|

|

|

|

|

|

Welded steel pipe fittings are available in beveled and plain ends

Welded pipe fitting which have beveled ends are commonly applied by the manufacturers manually or through automated process to make sure its stability. This gives a perfect combination with butt-weld fitting for simpler welding process.

Welded steel fittings which have plain ends are commonly used for strong, leak proof joint. Its end are smooth and doesn’t have any thread ends.

HS Code for Welded Pipe Fittings

| Product | HS Code |

|---|---|

| Welded fittings | 73072300 |

Welded Carbon Steel Fittings Benefits

- Allow thin thickness (SCH 10 or SCH 10S)

- Various sizes (1/4″ to 24″)

- Many possibilities for twisting and ease of welding

- Butt weld saves more cost than socket weld or threaded

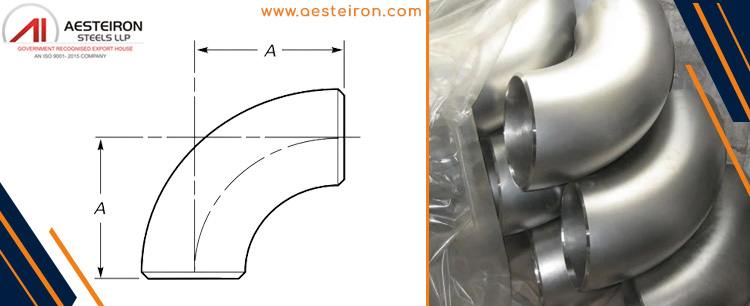

ASME B16.9 Buttweld Elbow Dimension

| NPS | 1 | 01 1/4 | 01 1/2 | 2 | 02 1/2 | 3 | 03 1/2 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|---|---|---|

| O.D mm | 33.4 | 42.2 | 48.3 | 60.3 | 73 | 88.9 | 101.6 | 114.3 | 141.3 | 168.3 |

| inch | 1.32 | 1.66 | 1.9 | 2.38 | 2.88 | 3.5 | 4 | 4.5 | 5.56 | 6.62 |

| A mm | 25 | 32 | 38 | 51 | 64 | 76 | 89 | 102 | 127 | 152 |

| inch | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 |

| NPS | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | |

| O.D mm | 219.1 | 273 | 323.8 | 355.6 | 406.4 | 457 | 508 | 559 | 610 | |

| inch | 8.62 | 10.75 | 12.75 | 14 | 16 | 18 | 20 | 22 | 24 | |

| A mm | 203 | 254 | 305 | 356 | 406 | 457 | 508 | 559 | 610 | |

| inch | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

Welded Buttweld Pipe Fittings can be manufactured in various types and wall thickness

It can be manufactured in several types and wall thickness in order to be used in broad scope of applications and environment. Various piping system are used in different temperature and pressure conditions, where pipe fitting needs suitable strength and longetivity.

Hence by wide range of wall thicknesses i.e. both thicker and thinner whatever the application demands, the manufacturers can provide their pipe fitting accordingly which can tolerate certain pressure without getting damage.

What is welded fittings?

- Components used to connect, direct, or change the direction of pipes

- Provides strong, durable, and leak-proof connections

- suitable for high pressures and harsh environments

- Types: elbows, tees, reducers, stub end, and caps

Welded black iron fittings connect pipes using a weld for a robust connection

Welded black iron fitting which are connected to pipes gives permanent, leak-proof connection. This kind of connection gives resistance against high pressure and temperature applications.

The robust connection are involves the usage of heat to melt Welded black iron fitting and joint to the elements, which gives permanent attachment. This process gives high strength, leak resistance and safety to the pipe fitting.

Difference Between Seamless and Welded Fittings

| Features | Seamless Fittings | Welded Fittings |

|---|---|---|

| Manufacturing | Made from single piece of metal without joints or seams | Made by welding together separate pieces of metal |

| Strength | stronger due to the absence of seams | slightly reduced strength at the weld joint |

| Durability | durable and less prone to failure | susceptible to weld defects |

| Cost | more expensive | less expensive |

| Pressure ratings | Higher | Lower |

| Flexibility | Less | designed with more variations in shape and size |

| Surface finish | smooth surface finish | may vary depending on the welding process |

| Heat Treatment | requires less heat treatment post-production | requires heat treatment post-welding to relieve stresses |

| Weight | consistent weight due to uniform wall thickness | depend on the thickness of welds and additional components. |

| Application | oil and gas, aerospace, and chemical processing | lower-pressure systems like water and HVAC |

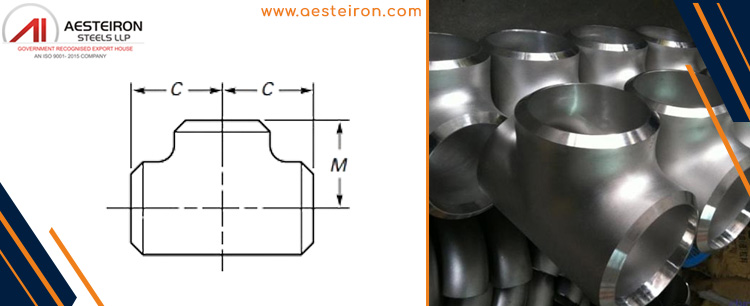

Welded Tee Dimension

| NPS | Â | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 5 | 6 | 8 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O.D | mm | 21.3 | 26.7 | 33.4 | 42.2 | 48.3 | 60.3 | 73 | 88.9 | 101.6 | 114.3 | 141.3 | 168.3 | 219.1 |

| inch | 0.84 | 1.05 | 1.32 | 1.66 | 1.9 | 2.38 | 2.88 | 3.5 | 4 | 4.5 | 5.56 | 6.62 | 8.62 | |

| C | mm | 25 | 29 | 38 | 48 | 57 | 64 | 76 | 86 | 95 | 105 | 124 | 143 | 178 |

| inch | 1 | 1.12 | 1.5 | 1.88 | 2.25 | 2.5 | 3 | 3.38 | 3.75 | 4.12 | 4.88 | 5.62 | 7 | |

| M | mm | 25 | 29 | 38 | 48 | 57 | 64 | 76 | 86 | 95 | 105 | 124 | 143 | 178 |

| inch | 1 | 1.12 | 1.5 | 1.88 | 2.25 | 2.5 | 3 | 3.38 | 3.75 | 4.12 | 4.88 | 5.62 | 7 | |

| NPS | Â | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32 | 36 |

| O.D | mm | 273 | 323.8 | 355.6 | 406.4 | 457 | 508 | 559 | 610 | 660 | 711 | 762 | 813 | 914 |

| inch | 10.75 | 12.75 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32 | 36 | |

| C | mm | 216 | 254 | 279 | 305 | 343 | 381 | 419 | 432 | 495 | 521 | 559 | 597 | 673 |

| inch | 8.5 | 10 | 11 | 12 | 13.5 | 15 | 16.5 | 17 | 19.5 | 20.5 | 22 | 23.5 | 26.5 | |

| M | mm | 216 | 254 | 279 | 305 | 343 | 381 | 419 | 432 | 495 | 521 | 559 | 597 | 673 |

| inch | 8.5 | 10 | 11 | 12 | 13.5 | 15 | 16.5 | 17 | 19.5 | 20.5 | 22 | 23.5 | 26.5 |

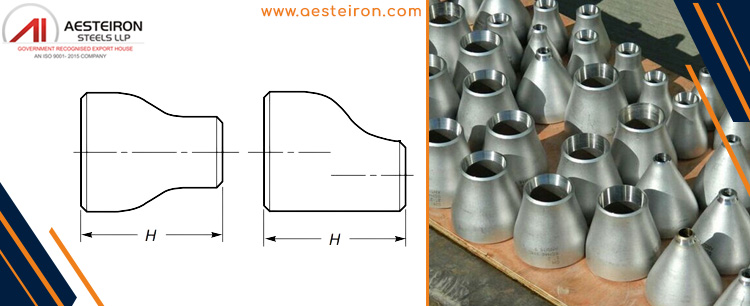

Welded Pipe Reducer Dimensions

| NPS | 3/4 x 1/2 | 3/4 x 3/8 | 1 x 3/4 | 1 x 1/2 | 1-1/4 x 1 | 1-1/4 x 3/4 | 1-1/4 x 1/2 | 1-1/2 x 1-1/4 | 1-1/2 x 1 | 1-1/2 x 3/4 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| O.D L | mm | 26.7 | 26.7 | 33.4 | 33.4 | 42.2 | 42.2 | 42.2 | 48.3 | 48.3 | 48.3 |

| O.D S | mm | 21.3 | 17.3 | 26.7 | 21.3 | 33.4 | 26.7 | 21.3 | 42.2 | 33.4 | 26.7 |

| H | mm | 38 | 38 | 51 | 51 | 51 | 51 | 51 | 64 | 64 | 64 |

| NPS | 1-1/2 x 1/2 | 2 x 1-1/2 | 2 x 1-1/4 | 2 x 1 | 2 x 3/4 | 2-1/2 x 2 | 2-1/2 x 1-1/2 | 2-1/2 x 1-1/4 | 2-1/2 x 1 | 3 x 2-1/2 | |

| O.D L | mm | 48.3 | 60.3 | 60.3 | 60.3 | 60.3 | 73 | 73 | 73 | 73 | 88.9 |

| O.D S | mm | 21.3 | 48.3 | 42.2 | 33.4 | 26.7 | 60.3 | 48.3 | 42.2 | 33.4 | 73 |

| H | mm | 64 | 76 | 76 | 76 | 76 | 89 | 89 | 89 | 89 | 89 |

Accessories,ball pump,soccer ball pump,air pump for ball

Jiangyin Mingde Sports Goods Co., Ltd. , https://www.mdsportsball.com