Understanding Solid Carbide End Mills: Types and Applications

Â

What Are Carbide Cutters?

Carbide cutters are tools manufactured from a rod of tungsten carbide, which is essentially a combination of raw tungsten and cobalt. These rods are precision-ground using CNC machines to create specific shapes tailored for various applications, primarily featuring flat and round designs.

(Image - 1)

On the left side of Image (1), you can see a raw carbide rod, while the right side displays an uncoated flat carbide end mill with three flutes, crafted by a grinding machine. Typically, carbide cutters are coated with various systems to enhance their wear resistance, durability, and overall performance.

(Image - 2)

Types of Cutters

Flat End Mill

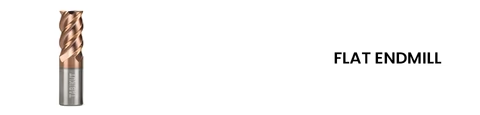

(Image - 3)

Flat end mills are characterized by a flat top surface and form a 90-degree angle at the top. They come in varieties of two, three, four, and six flutes, with four-flute models being the most commonly used across industries. Two-flute designs are ideal for roughing operations on softer materials, whereas three-flute versions are often employed for semi-finishing non-ferrous materials due to their efficient chip evacuation capabilities.

These tools are predominantly utilized in face milling, slotting, plunging, shoulder milling, pocketing, and creating 90-degree profiles in components or dies. They excel in finishing tasks during facing and side milling operations. However, they cannot be used for drilling purposes.

Â

Ball Nose End Mill

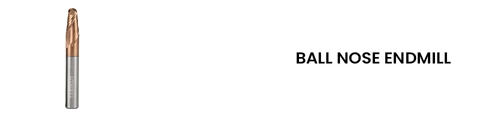

(Image - 4)

As the name suggests, ball nose end mills feature a spherical tip, offering a full radius design. For instance, a 12mm ball nose end mill has a radius of 6mm. These tools are invaluable for 3D milling, pocketing, and achieving precise radius finishes on components. Ball nose end mills are not suitable for drilling operations either.

Â

Corner Radius End Mill

(Image - 5)

Corner radius end mills closely resemble flat end mills but feature rounded edges. This design helps distribute cutting forces more evenly and improves shock absorption, making them highly effective for operations requiring corner radii in sizes ranging from 0.5mm to 3mm, depending on the application.

Â

Roughing End Mill

(Image - 6)

Roughing end mills are designed specifically for heavy-duty cutting stages where a subsequent finishing operation is required. Their primary advantage lies in reducing vibrations during machining. Additionally, they are excellent for scenarios where chip evacuation poses challenges, such as in deep drill holes. The unique design of roughing end mills breaks chips into smaller fragments, facilitating easier chip removal.

Â

Long Neck End Mill

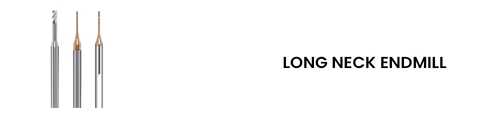

(Image - 7)

Long-neck square end mills and ball nose end mills reduce the shank diameter to access deeper areas while maintaining the same cutting flute length. This design does not increase the side cutting capability but provides greater reach for operations requiring depth.

Â

Three Flute End Mill

(Image - 8)

Three-flute end mills are commonly used for softer materials like aluminum, brass, silver, and copper. Fewer flutes are necessary for softer materials, allowing for efficient material removal. Even without diamond-like carbon (DLC) coatings, these tools perform exceptionally well.

Â

What Are Flutes and Their Usage? 1, 2, 3, 4, 5, 6

The number of flutes directly impacts the load on each tooth, affecting the tool's performance. More flutes result in reduced load per tooth, improving surface finish in finishing operations. However, more flutes require higher feed rates and lower spindle speeds to maximize tool life.

Single-flute end mills, also known as one-flute carbide end mills, are ideal for soft materials like plastics, acrylics, wood, and aluminum in router applications. They allow for high-volume material removal.

Two-flute end mills are widely used for steel, stainless steel, cast iron, and non-ferrous materials in semi-finishing operations. Their larger flute spaces facilitate better chip evacuation.

Three-flute end mills are versatile, suitable for both ferrous and non-ferrous materials. They strike a balance between chip evacuation and material removal efficiency.

Four-flute end mills are the most prevalent in the industry, particularly for steel, stainless steel, and cast iron. They enable faster feeds and efficient chip removal, though the surface finish may not be as smooth as with fewer flutes.

Five-flute or higher-end mills are primarily used for ultra-fine finishes. While they offer superior surface quality, they are costly and can pose challenges in chip evacuation, especially with larger diameters.

Â

Coatings

Coatings are thin layers applied to enhance wear resistance, heat tolerance, and tool hardness. Different coatings offer distinct advantages, but they are just one aspect of a cutter's quality. I'll delve deeper into carbide coatings in my next article.

Perfume Boxes,personalized box packaging,lip stick packaging box,beauty product packaging box

Zhuhai Yingwei Packing Products Co., LTD , https://www.yingweipacking.com