How Robotic Welding Boosts Productivity for Manufacturers of Large Transportation Components

Robotic welding has become a game-changer for manufacturers in the transportation industry, especially those producing large and complex parts. While many may think robotic welding is best suited for small, repetitive tasks, modern robotic systems are now capable of handling large-scale components with precision, speed, and consistency.

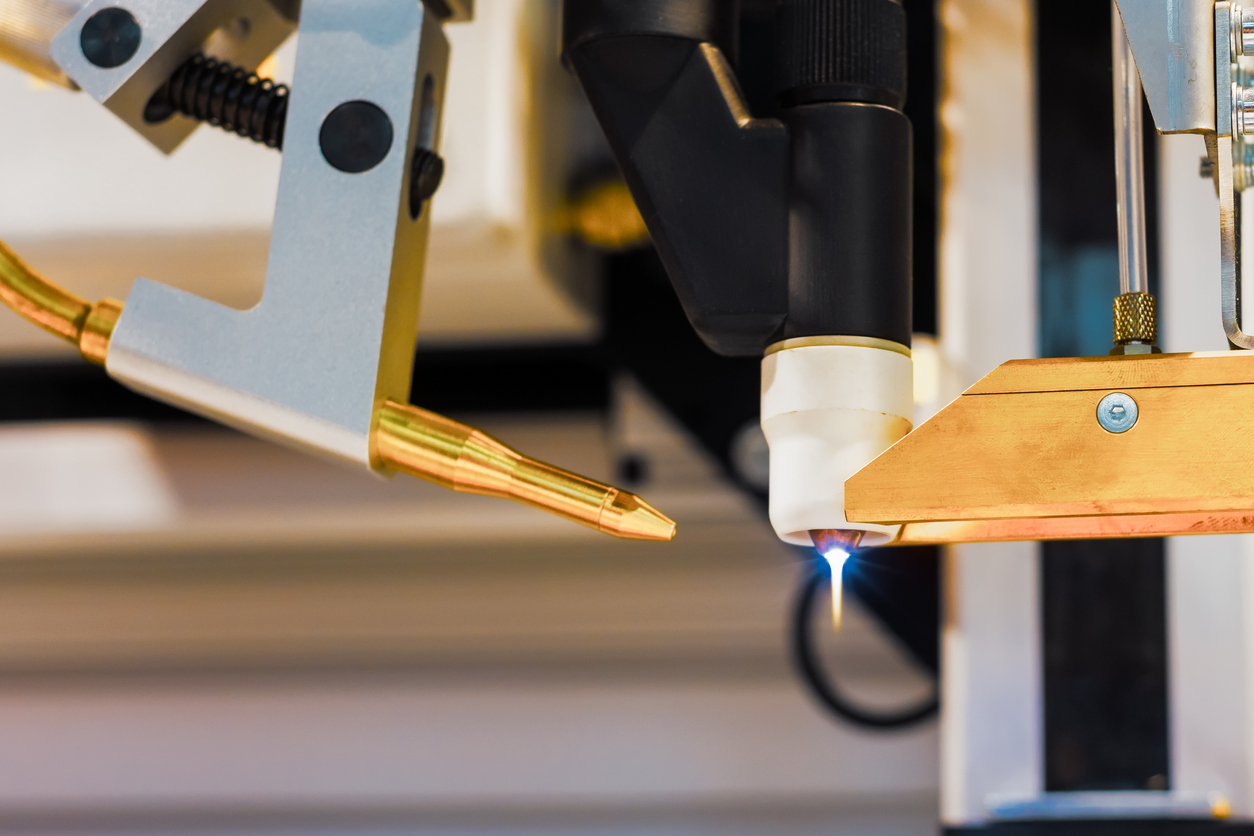

These advanced systems often include multiple robots equipped with sophisticated software and control systems to ensure high-quality welds. Compared to traditional manual welding, which can be slow, error-prone, and labor-intensive, robotic welding significantly enhances productivity and reduces costs over time.

Key Features of an Effective Robotic Welding Work Cell for Transportation Manufacturing

For large parts, robotic welding work cells typically require extensive offline programming using simulation software. This helps prevent collisions and ensures smooth operation during the welding process. The precise programming also allows the robot arms to maximize their reach, which is essential when working on oversized components.

Mobility is another crucial factor. By using servo-driven tracks—either mounted near or above the part—robots can access hard-to-reach areas that would otherwise be difficult for stationary systems. This not only improves flexibility but also increases the overall efficiency of the welding process.

Realizing ROI with Robotic Welding: A Case Study from a Tier-1 Trailer Manufacturer

A leading trailer bed manufacturer recently faced challenges with high defect rates and slow production due to manual welding. To address these issues, they partnered with Genesis Systems to implement a custom, turn-key robotic welding solution.

The new system featured a two-station design that streamlined loading and unloading, reducing downtime and increasing throughput. With two robots working in tandem, the system could perform multiple welds simultaneously, improving both speed and quality. This led to faster production cycles and fewer rework instances.

As a result, the company saw a quick return on investment, reduced lead times, and lowered production costs. The implementation of robotic welding not only solved their immediate challenges but also positioned them for long-term growth and competitiveness.

If you're interested in learning more about how robotic welding can transform your manufacturing process, check out the full case study on Genesis Systems’ robotic welding solution for a tier-1 transportation manufacturer.

Posted in Robotic Welding50H Narrow-body Fuel Dispenser

Double Hoses Fuel Dispenser,Single Product Submersible Pump Type Fuel Dispenser ,Single Hose Fuel Dispenser,Double Products Submersible Pump Type Fuel Dispenser

Henan Wenjia Energy Technology Co., Ltd , https://www.hnwjny.com