Congratulations on the Successful Development of PCBWay's 24-Layer, 6-Order Arbitrary Interconnection HDI PCB

With the rapid advancement of integrated circuit technology, the complexity of chip-to-chip connections has significantly increased. Traditional PCB solutions are struggling to meet the demands of high-frequency and high-speed applications. Ensuring stable and reliable interconnections between high-density and high-speed chips has become a critical challenge in modern electronics.

In addition, as chip power consumption continues to rise, so does heat generation. This necessitates advanced cooling systems to ensure optimal performance and prevent overheating, which could otherwise lead to system failures or reduced lifespan of components.

As a result, a new type of PCB called the "interposer PCB" has emerged as a game-changer in the industry.

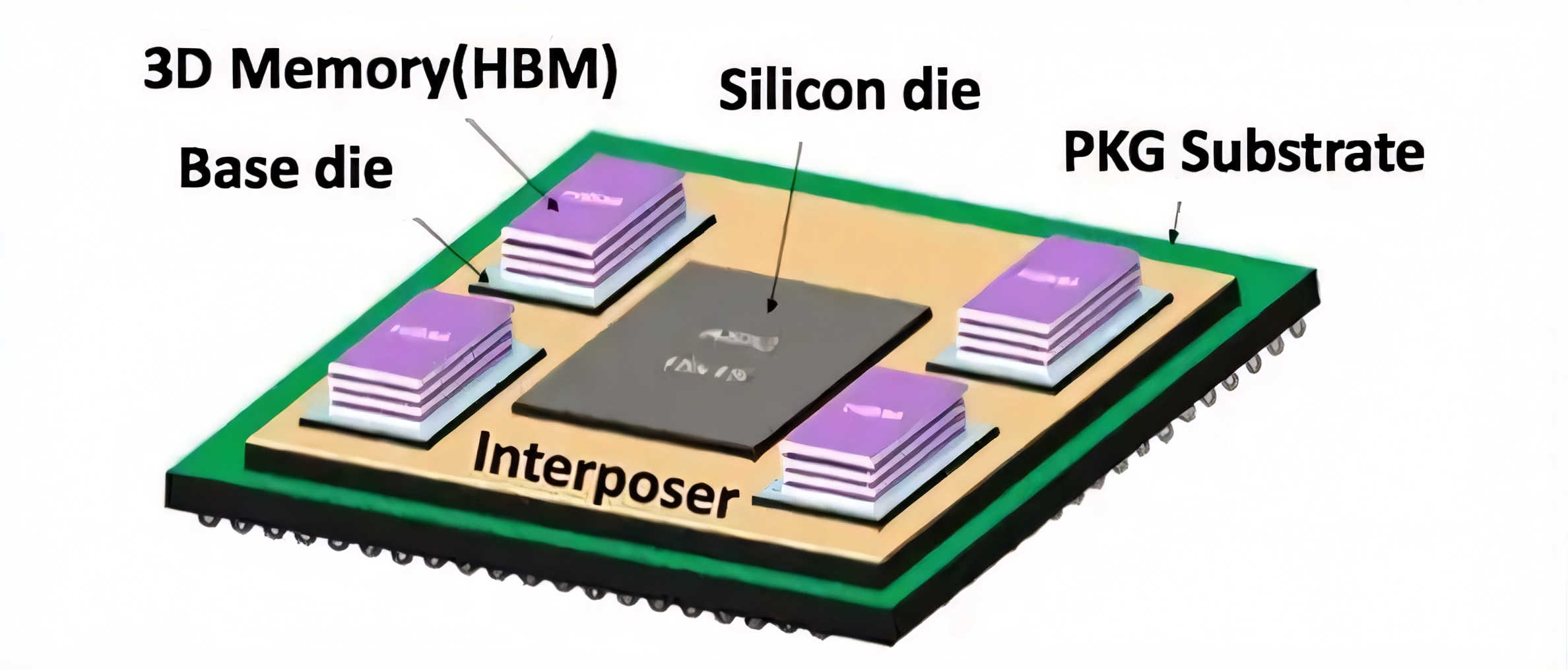

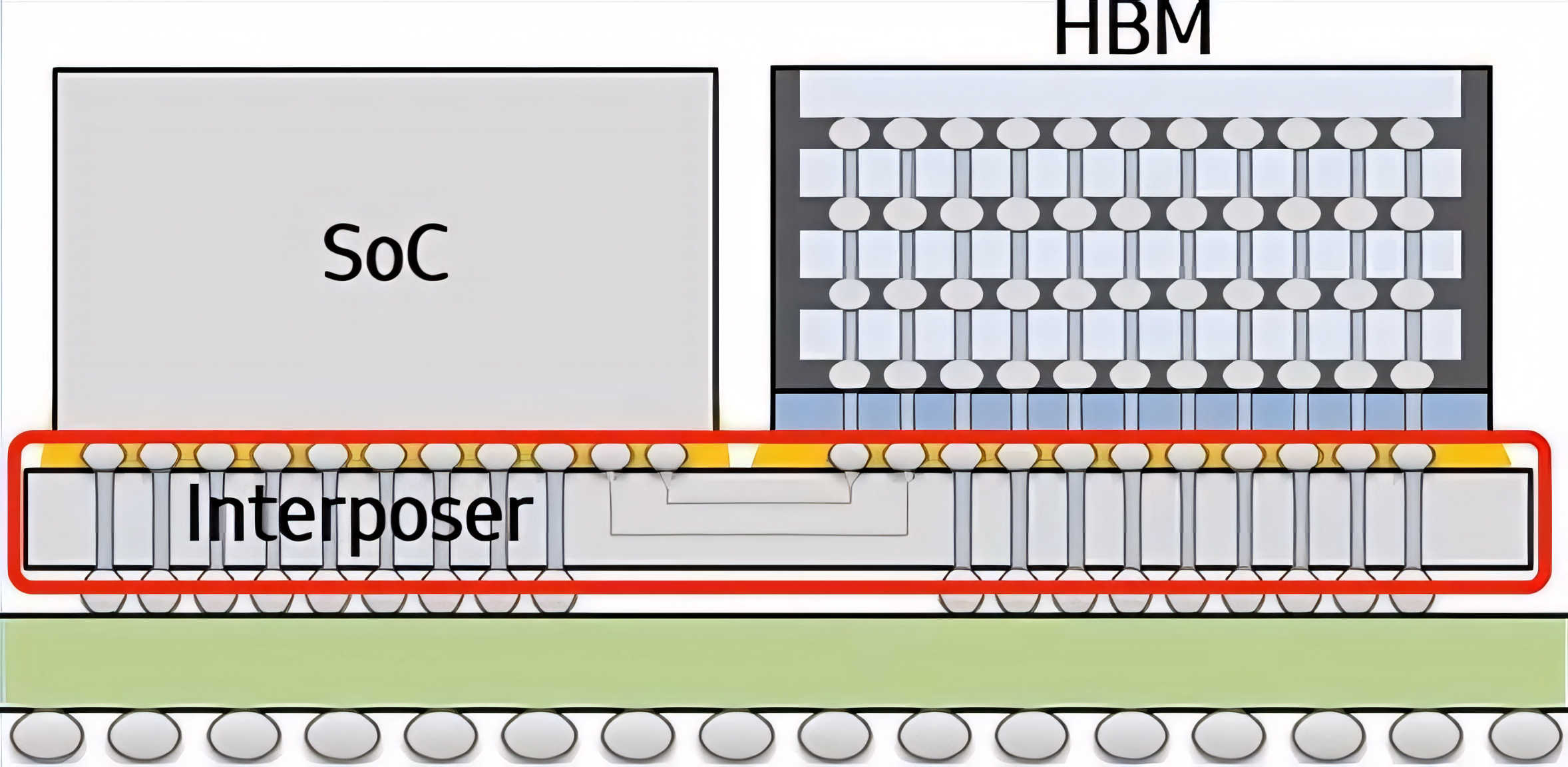

An interposer PCB is a highly advanced, high-layer HDI (High-Density Interconnect) board that enables complex, multi-directional interconnections. It acts as an intermediary layer between different electronic components, facilitating seamless communication between chips. This is achieved through pad leads that connect to micro bumps (uBumps) on the chip, as well as routing within the interposer layer. The use of through-silicon vias (TSVs) allows vertical connectivity between upper and lower layers, enhancing signal integrity and performance.

The design of interposer PCBs includes inner layers connected to outer layers via laser microvias and dense routing. This results in a multi-layer structure with BGA (Ball Grid Array) connections on the top side and direct pad connections on the bottom, offering greater flexibility and reliability in high-performance applications.

Interposer PCBs play a vital role in improving the performance, efficiency, and reliability of integrated circuits. Here’s how:

First, they enable faster and more reliable connections for semiconductor devices. By using high-performance materials, interposer PCBs support short-distance, high-density connections, significantly boosting data transmission speeds between chips.

Second, interposer technology helps reduce signal loss and improve signal integrity by minimizing the length of signal paths. This is especially beneficial in high-speed and high-frequency applications where even minor signal degradation can impact performance.

Third, the interposer layer also serves as a thermal management solution, helping to dissipate heat more efficiently and keep chip temperatures under control.

Finally, interposer PCBs allow for the integration of heterogeneous chips, enabling efficient communication between different types of components. This makes them ideal for complex systems such as AI accelerators, multi-core processors, and high-bandwidth memory modules.

In conclusion, interposer PCBs have found widespread application in fields like high-performance computing, artificial intelligence, data centers, and telecommunications. In high-performance computing, they enable the connection of multiple processing units, allowing for scalable and powerful systems. In AI, they help accelerate neural network training and inference. In data centers and communications, they provide higher bandwidth and faster data transfer rates, meeting the growing demands of big data and 5G networks.

As a leading manufacturer of high-end HDI PCBs, PCBWay continuously innovates to meet evolving market needs. We have successfully developed high-layer, high-order Anylayer interposer PCBs, overcoming significant technical challenges in the process.

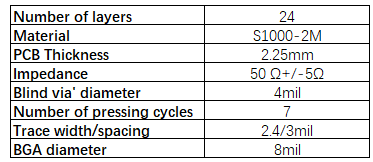

Here, we present the details of our latest product: a 24-layer, 6-order Anylayer HDI PCB.

1. Product Parameters

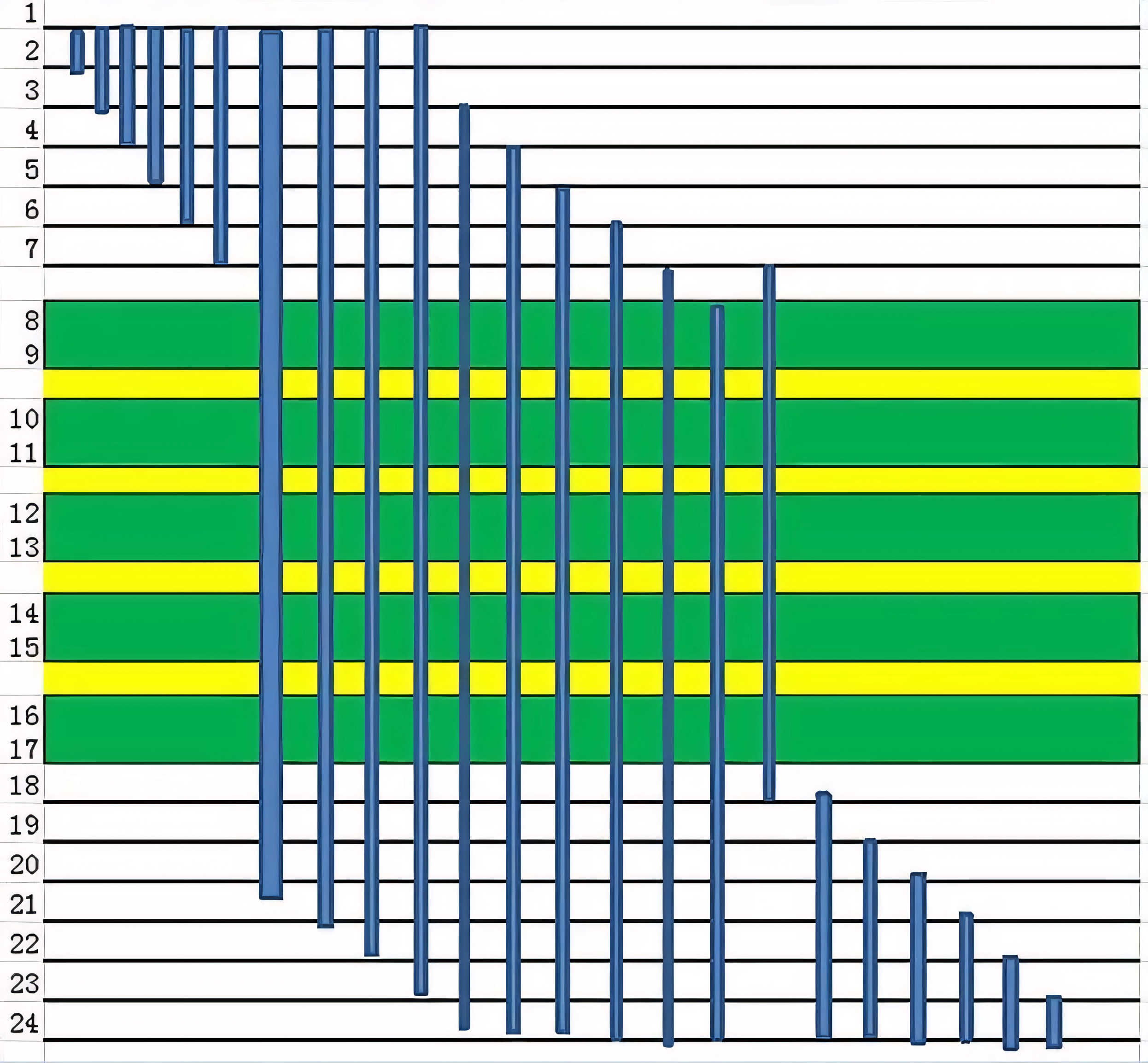

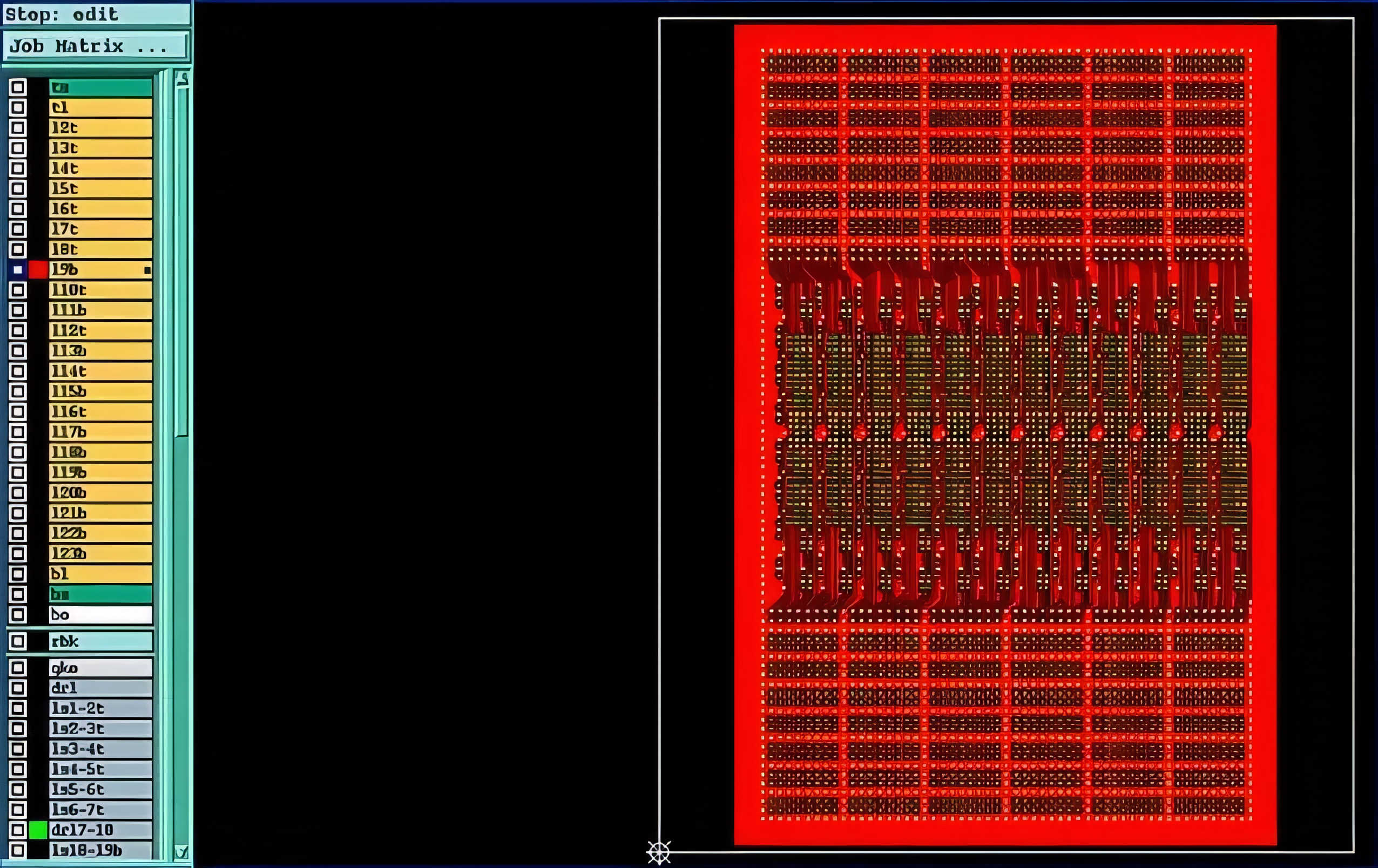

2. Product Structure

3. Technical Challenges

Challenge 1: The buried via thickness from L7 to L18 is 1.0 mm, with a mechanical via diameter of 0.1 mm, resulting in a 10:1 aspect ratio, making drilling extremely difficult.

Challenge 2: The BGA pitch is 0.35 mm, and the distance between the via and the conductor trace is only 0.13 mm, increasing the risk of misalignment during multiple laminations.

Challenge 3: The trace width and spacing are 2.4 mil and 3 mil respectively, requiring dense routing. Below is a sample of the routing layout.

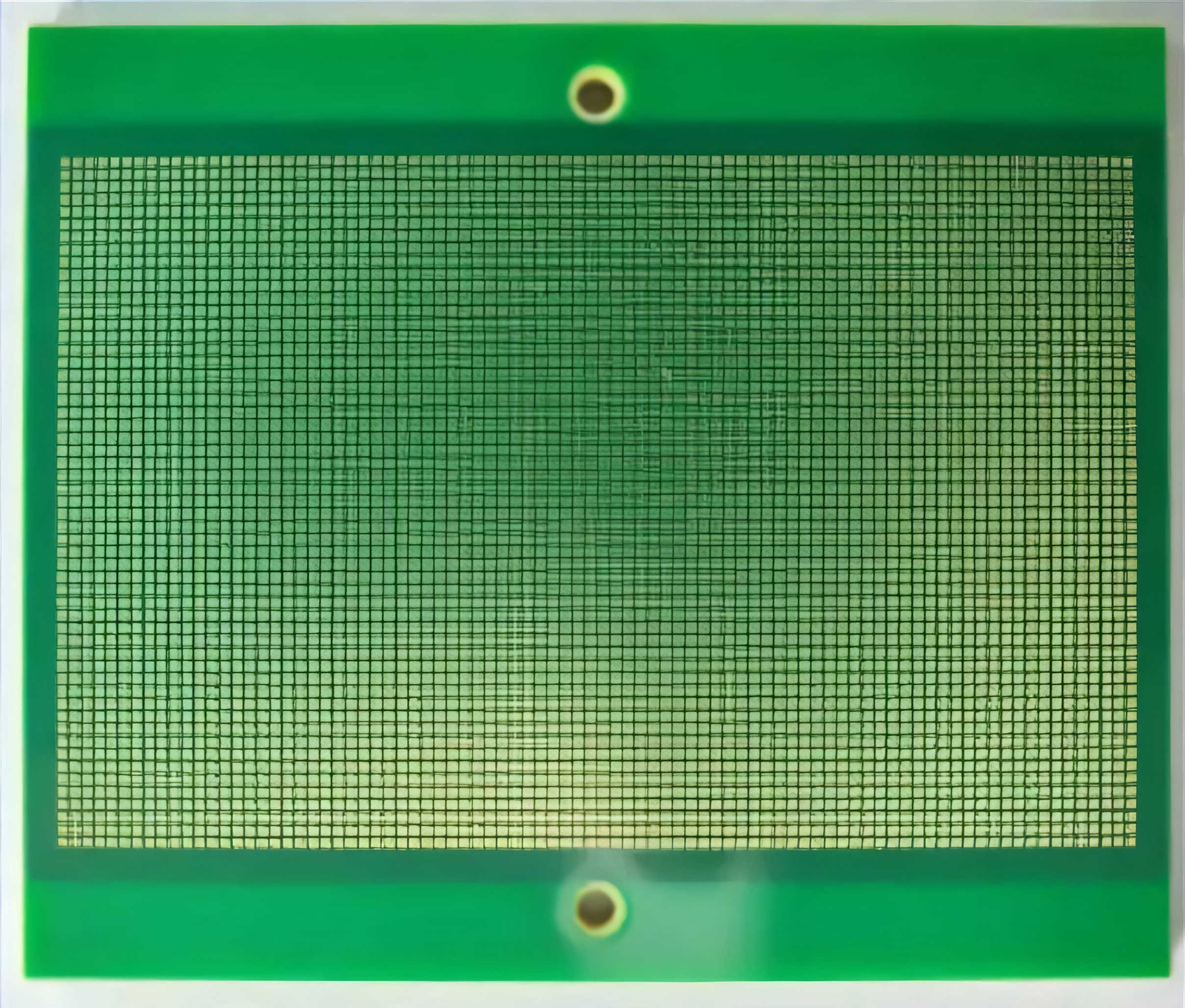

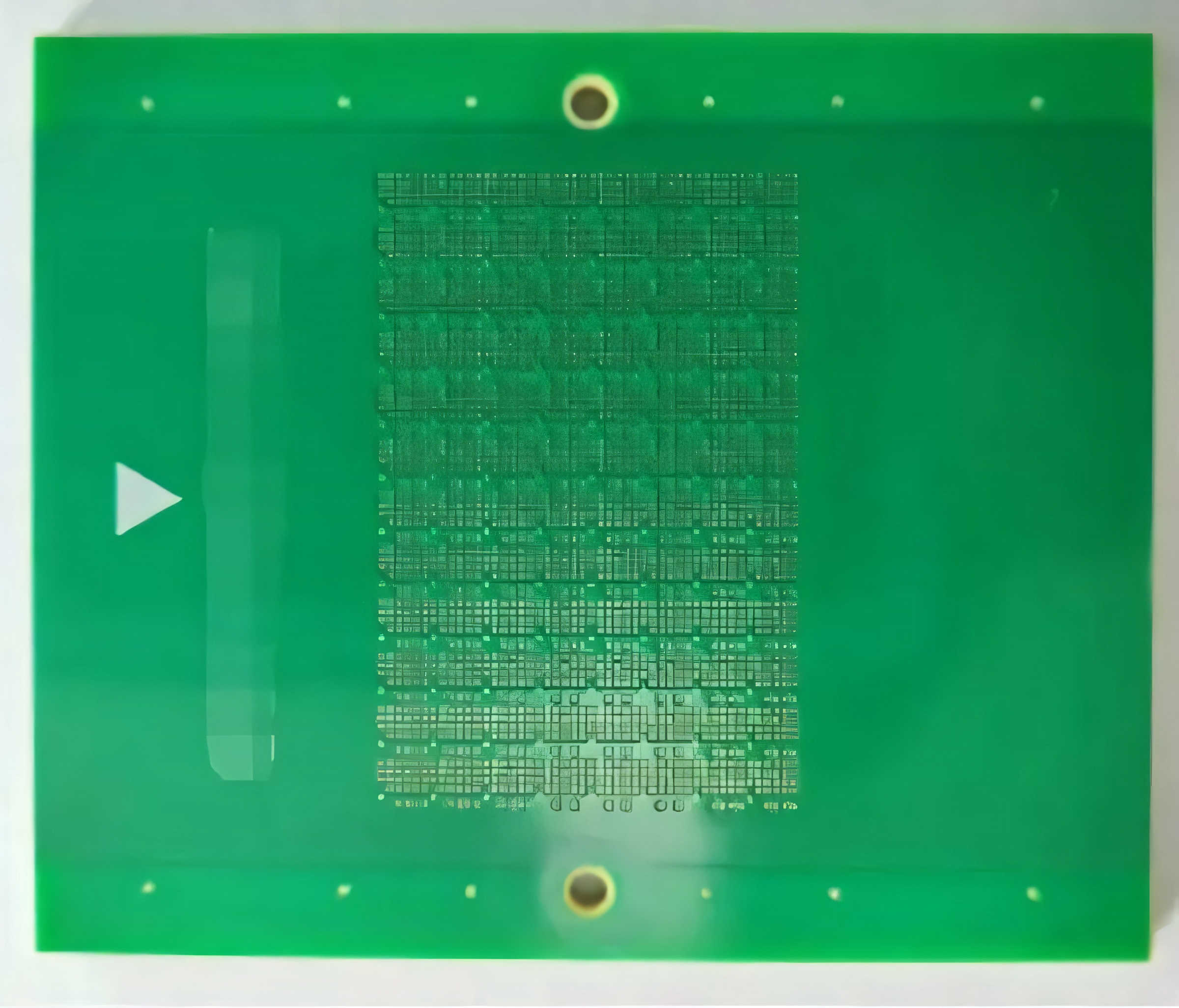

4. Finished Product Images

JIANGMEN PRO-TAYLOR REFRIGERATION CO., LTD. , https://www.protaylor.com