Model NO.: 4WE6D61CG24N9Z5L

Power Supply: DC Solenoid Valve

Usage: Drain

Standard: DIN

Application: Industrial Usage

Size: Ng6

Trademark: Power or OEM

Specification: ISO9001

Origin: Ningbo

HS Code: 84812010

Model NO.: 4WE6D61CG24N9Z5L

Power Supply: DC Solenoid Valve

Usage: Drain

Standard: DIN

Application: Industrial Usage

Size: Ng6

Trademark: Power or OEM

Specification: ISO9001

Origin: Ningbo

HS Code: 84812010

china directional hydraulic valves rexroth

Product Information

-

- Porting pattern to DIN 24 340 form A,

- ISO 4401 and CETOP-RP 121 H- Wet pin DC or AC solenoids with removable coil- Solenoid coil can be rotated through 90¡ã- It is not necessary to drain oil when the coil is replaced- Fault override button, optional- Waterproof pin plug, optionalÂ- Large-scope suitable voltage, optional -

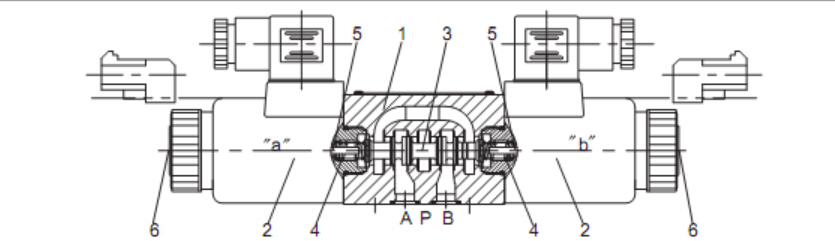

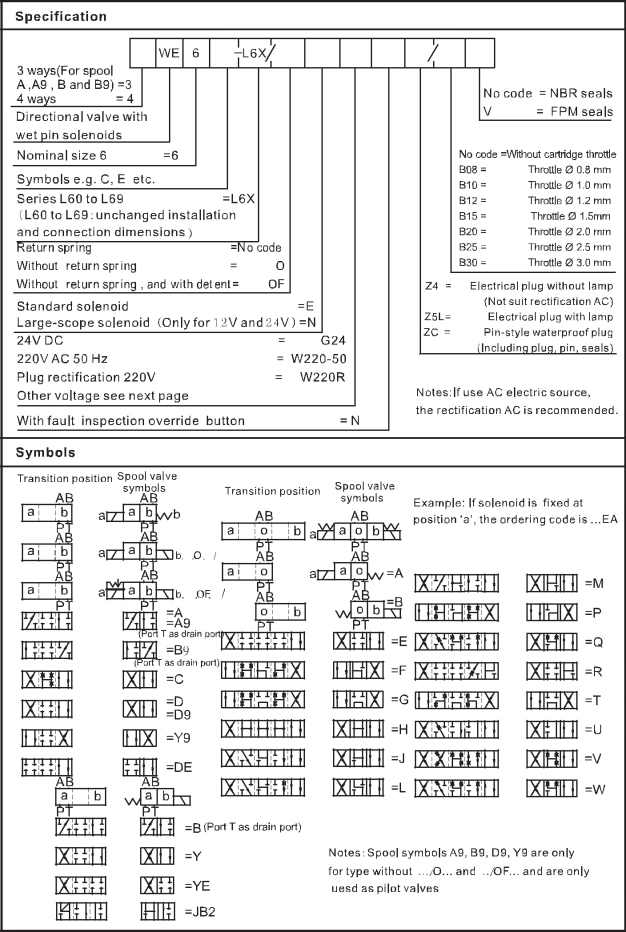

ÂType WE valves are solenoid operated directional spool valves. They control the start, stop and direction ofÂflow.The directional control valves consist of housing (1), one or two solenoids (2), the control spool (3), and one orÂtwo return springs (4).In the de-energised condition the control spool (3) is held in the neutral or initial position by means of returnÂsprings (4) (except for impulse spools). The control spool (3) is actuated via wet pin solenoids (2).To guarantee satisfactory operation care should be taken to ensure that the solenoid pressure chamber is filledÂwith oil.The control spool(3) is moved to the expected position by solenoid(2) and pushing rod(5). This gives free-flowÂfrom P to A and B to T or P to B and A to T.When solenoid (2) is de-energised, the control spool (3) is returned to its initial position by means of the returnÂsprings (4).ÂThe solenoids may also control the control spool (3) by an optional override button(6)  under the de-energisedÂcondition.Type 4WE 6.. L6X/O...(only possible for symbols A, C and D)This version has 2 switched positions and 2 solenoids without detent. ÂType 4WE 6.. L6X/OF... (impulse spool, only for symbols A, C and D)This version has 2 switched positions, 2 solenoids and a detent. Both switched positions are thus fixedÂalternately and so it is unnecessary to continually energise the solenoid.Cartridge throttle (type 4WE 6..L6X/¡-/B.. )The cartridge throttle is necessary since actual flow may be larger than theÂperformance limits of the valve during switching process.This is inserted in the P channel of the directional control valve.For application in voltage pulsation, solenoids with large scope voltageare recommended.For application in high protective grade, waterproof plug should be used.

ÂType WE valves are solenoid operated directional spool valves. They control the start, stop and direction ofÂflow.The directional control valves consist of housing (1), one or two solenoids (2), the control spool (3), and one orÂtwo return springs (4).In the de-energised condition the control spool (3) is held in the neutral or initial position by means of returnÂsprings (4) (except for impulse spools). The control spool (3) is actuated via wet pin solenoids (2).To guarantee satisfactory operation care should be taken to ensure that the solenoid pressure chamber is filledÂwith oil.The control spool(3) is moved to the expected position by solenoid(2) and pushing rod(5). This gives free-flowÂfrom P to A and B to T or P to B and A to T.When solenoid (2) is de-energised, the control spool (3) is returned to its initial position by means of the returnÂsprings (4).ÂThe solenoids may also control the control spool (3) by an optional override button(6)  under the de-energisedÂcondition.Type 4WE 6.. L6X/O...(only possible for symbols A, C and D)This version has 2 switched positions and 2 solenoids without detent. ÂType 4WE 6.. L6X/OF... (impulse spool, only for symbols A, C and D)This version has 2 switched positions, 2 solenoids and a detent. Both switched positions are thus fixedÂalternately and so it is unnecessary to continually energise the solenoid.Cartridge throttle (type 4WE 6..L6X/¡-/B.. )The cartridge throttle is necessary since actual flow may be larger than theÂperformance limits of the valve during switching process.This is inserted in the P channel of the directional control valve.For application in voltage pulsation, solenoids with large scope voltageare recommended.For application in high protective grade, waterproof plug should be used.

china directional hydraulic valves rexroth

Product Information

-

- Porting pattern to DIN 24 340 form A,

- ISO 4401 and CETOP-RP 121 H- Wet pin DC or AC solenoids with removable coil- Solenoid coil can be rotated through 90¡ã- It is not necessary to drain oil when the coil is replaced- Fault override button, optional- Waterproof pin plug, optionalÂ- Large-scope suitable voltage, optional -

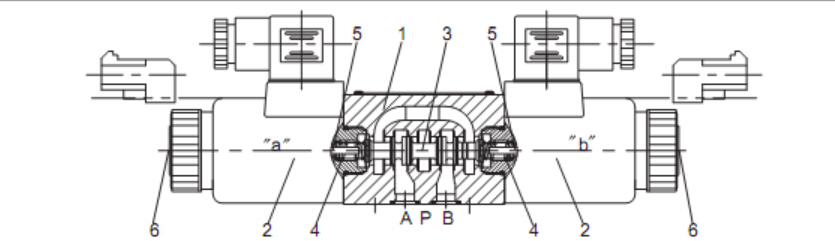

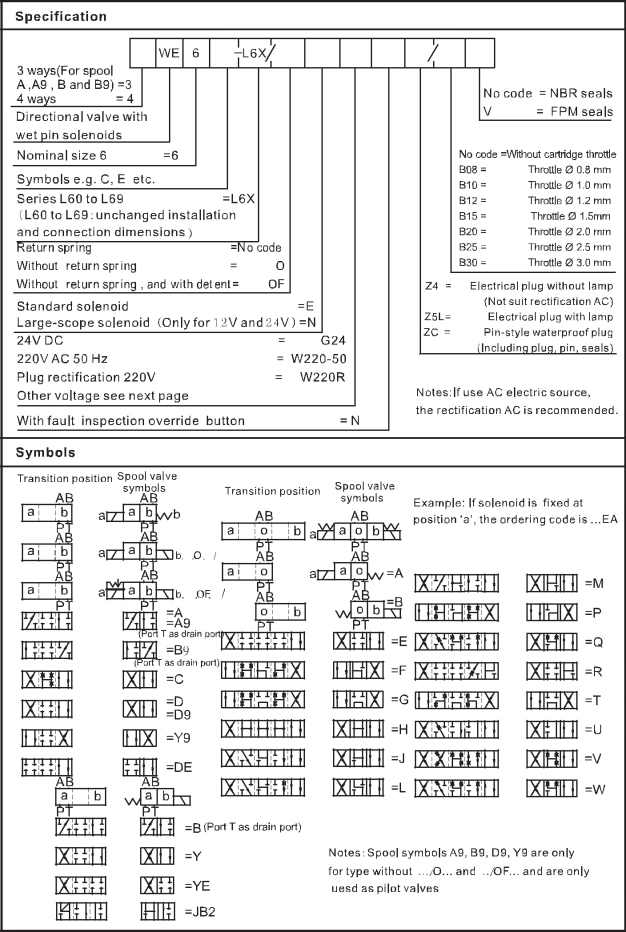

ÂType WE valves are solenoid operated directional spool valves. They control the start, stop and direction ofÂflow.The directional control valves consist of housing (1), one or two solenoids (2), the control spool (3), and one orÂtwo return springs (4).In the de-energised condition the control spool (3) is held in the neutral or initial position by means of returnÂsprings (4) (except for impulse spools). The control spool (3) is actuated via wet pin solenoids (2).To guarantee satisfactory operation care should be taken to ensure that the solenoid pressure chamber is filledÂwith oil.The control spool(3) is moved to the expected position by solenoid(2) and pushing rod(5). This gives free-flowÂfrom P to A and B to T or P to B and A to T.When solenoid (2) is de-energised, the control spool (3) is returned to its initial position by means of the returnÂsprings (4).ÂThe solenoids may also control the control spool (3) by an optional override button(6)  under the de-energisedÂcondition.Type 4WE 6.. L6X/O...(only possible for symbols A, C and D)This version has 2 switched positions and 2 solenoids without detent. ÂType 4WE 6.. L6X/OF... (impulse spool, only for symbols A, C and D)This version has 2 switched positions, 2 solenoids and a detent. Both switched positions are thus fixedÂalternately and so it is unnecessary to continually energise the solenoid.Cartridge throttle (type 4WE 6..L6X/¡-/B.. )The cartridge throttle is necessary since actual flow may be larger than theÂperformance limits of the valve during switching process.This is inserted in the P channel of the directional control valve.For application in voltage pulsation, solenoids with large scope voltageare recommended.For application in high protective grade, waterproof plug should be used.

ÂType WE valves are solenoid operated directional spool valves. They control the start, stop and direction ofÂflow.The directional control valves consist of housing (1), one or two solenoids (2), the control spool (3), and one orÂtwo return springs (4).In the de-energised condition the control spool (3) is held in the neutral or initial position by means of returnÂsprings (4) (except for impulse spools). The control spool (3) is actuated via wet pin solenoids (2).To guarantee satisfactory operation care should be taken to ensure that the solenoid pressure chamber is filledÂwith oil.The control spool(3) is moved to the expected position by solenoid(2) and pushing rod(5). This gives free-flowÂfrom P to A and B to T or P to B and A to T.When solenoid (2) is de-energised, the control spool (3) is returned to its initial position by means of the returnÂsprings (4).ÂThe solenoids may also control the control spool (3) by an optional override button(6)  under the de-energisedÂcondition.Type 4WE 6.. L6X/O...(only possible for symbols A, C and D)This version has 2 switched positions and 2 solenoids without detent. ÂType 4WE 6.. L6X/OF... (impulse spool, only for symbols A, C and D)This version has 2 switched positions, 2 solenoids and a detent. Both switched positions are thus fixedÂalternately and so it is unnecessary to continually energise the solenoid.Cartridge throttle (type 4WE 6..L6X/¡-/B.. )The cartridge throttle is necessary since actual flow may be larger than theÂperformance limits of the valve during switching process.This is inserted in the P channel of the directional control valve.For application in voltage pulsation, solenoids with large scope voltageare recommended.For application in high protective grade, waterproof plug should be used.

Connecting rods are vital components of internal combustion engines, including Mitsubishi engines. It connects the piston to the crankshaft and is responsible for converting the reciprocating motion of the piston into the rotational motion of the crankshaft. Mitsubishi connecting rods are typically made from high-strength steel or forged aluminum alloys to withstand the high stresses and temperatures generated by the engine. They are designed to be lightweight yet durable, ensuring efficient engine performance and service life.

Mitsubishi Connecting Rod,Auto Connecting Rod,Engine Connecting Rod,Engine Connecting Rods

Wuhu Hangtian Automobile Connecting Rod Co., Ltd , https://www.htconrod.com