Custom-Made Brass Electric Parts Based on Customer's Drawing (HS-BE-021)

Model NO.: HS-BE-021

Process: Forming Process

Industry: Metal Stamping Parts

Tolerances: 0.02mm

Customized: Yes

Material: Brass H65, H62, and C2680

Terms of Shipment: CIF, FOB, EXW

MOQ: 50,000 pieces

Finish: Nickel Plating

Trademark: OEM

Transport Package: 3,000 pcs per bag

Specification: CE, ROHS, SGS

Origin: Dongguan, China

HS Code: 7401000090

Custom-Made Brass Electric Parts as Per Customer’s Drawing (HS-BE-021)

We specialize in producing high-quality metal stamping parts using a wide range of stamping machines, from manual to precision punch presses. Depending on your order quantity, we provide the most cost-effective production solution, including laser cutting, single-shot, or continuous progressive die methods.

Our processing capabilities include: blanking, cutting, forming, rolling, drawing, bending, flaring, shrinking tubes, drilling, tapping, and spot welding for nuts or screws. The thickness range we can handle is from 0.2mm to 10mm.

Surface treatments available include plating, galvanization, anodizing, and powder coating.

| **Materials** | Carbon steel (cold rolled, galvanized), stainless steel, copper, brass, aluminum, etc. |

|---------------|----------------------------------------------------------------------------------|

| **Surface Treatment** | Polishing, zinc plating, nickel plating, chrome plating, powder coating, phosphate coating |

| **Equipment** | Stamping machines, automatic stamping machines, bending machines, welding machines, punching machines, lathes, riveting, grinding, brushing |

| **Size** | Customized according to customer’s design or sample |

| **Mould** | 1. We manufacture tooling based on customer drawings or samples. 2. We send samples for confirmation first. 3. Lifetime support with free maintenance |

| **Confirm Sample** | If the initial sample doesn’t meet expectations, we will modify the mold until the customer is satisfied |

| **Negotiation** | We discuss quality, quantity, price, delivery time, payment terms, and more |

| **Industries** | Furniture hardware, electronic components, construction machinery parts, metal processing machinery parts |

| **Packing** | Customized packaging according to customer requirements |

| **Delivery** | Delivered by sea or air, depending on customer preference |

With our advanced technology and professional team, we ensure precision, reliability, and timely delivery for all custom metal stamping projects. Whether you need small or large quantities, we are committed to meeting your needs and exceeding your expectations.

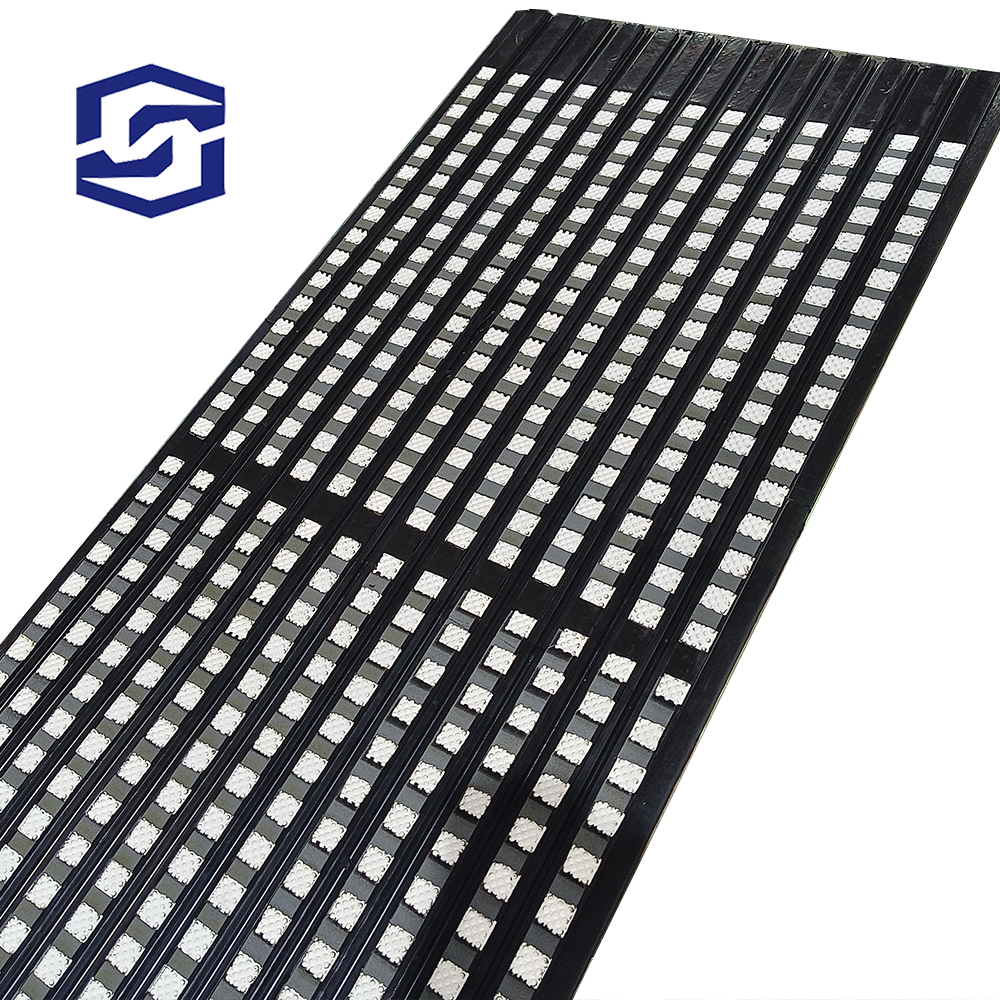

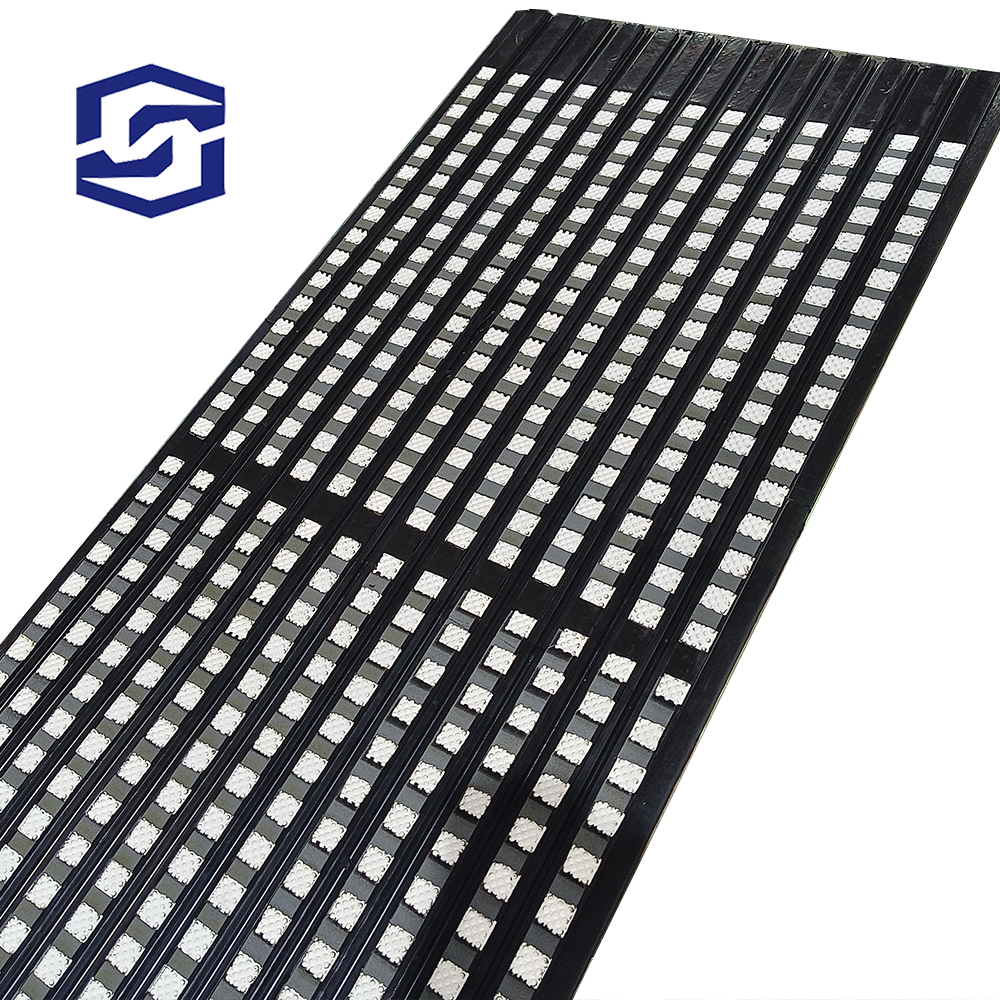

Wear resistant ceramic series, ceramic rubber sheet three-in-one composite liner combines the advantages of ceramic's high hardness and rubber's high cushioning, with wear resistant and impact resistant performance, which can solve the problem of anti-abrasion of the equipment in the process of conveying bulky materials and effectively reduce the environmental noise.

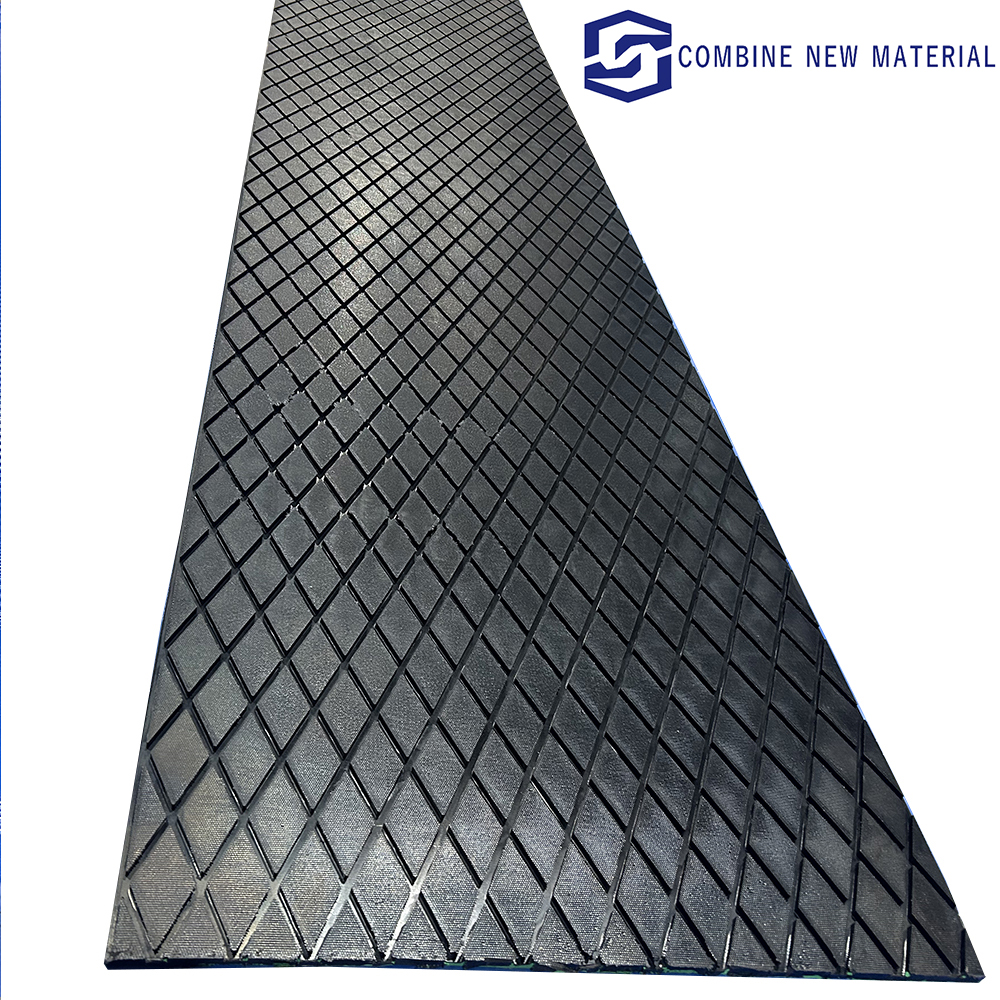

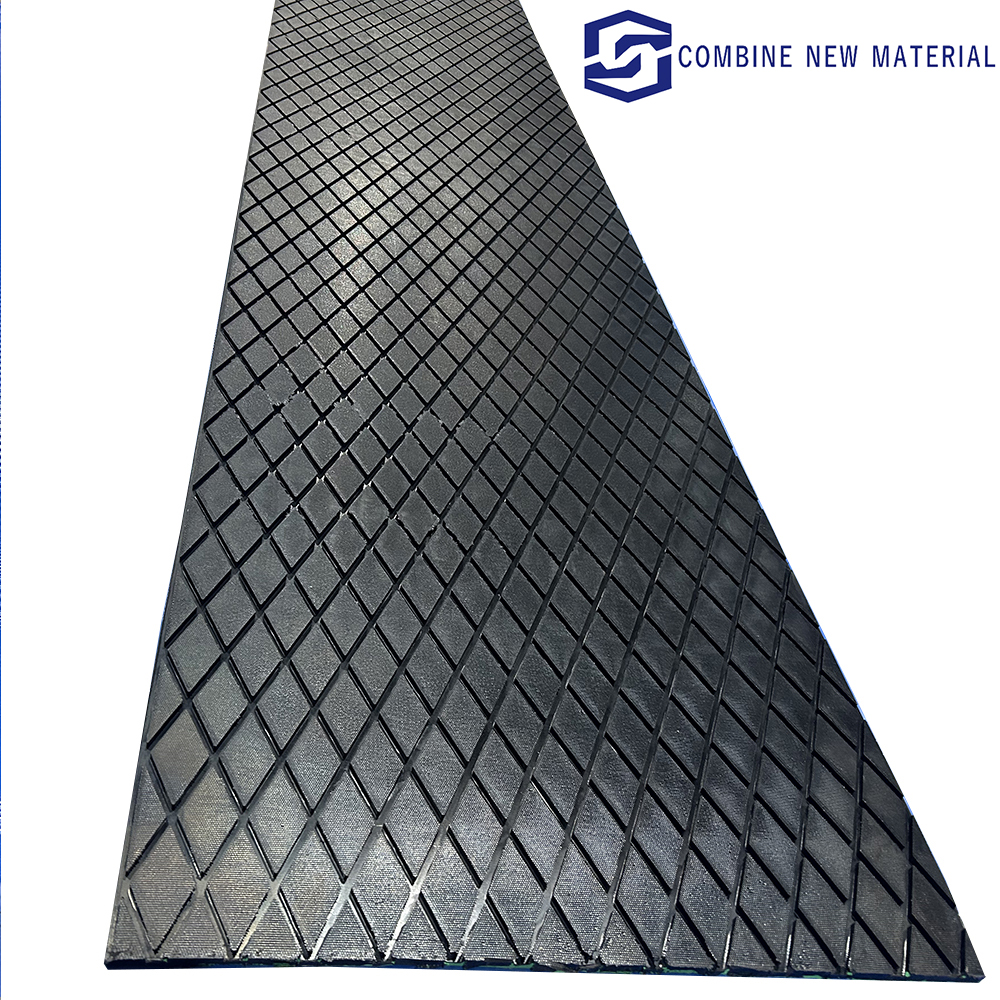

Roller covered is an important part of the belt conveyor transportation system, after covered the roller can effectively improve the operating conditions of the conveyor system, to protect the metal roller from wear and tear, rhombic pattern, ceramic rubber plate coating surface, can increase the friction on the surface of the rubber plate, to prevent the sliding friction between the roller and the belt to reduce the belt slipping, to reduce the roller surface of the material adhesion, so as to reduce the belt deflection and abrasion, so that the roller synchronized with the belt to ensure efficient operation of the belt.

pulley lagging,rubber sheet,wear resistant,ceramic rubber sheet,Three-in-one impact resistant ceramic composite liner

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com